- Home

- Common problems

- Pyrite

- Common problems

- Cracks

- Iron ochre

- Pyrite

- Crumbling concrete

- Foundation uplift

- Lateral warping

- Efflorescence

Pyrite

Problems relating to pyrite in the backfill beneath concrete slabs

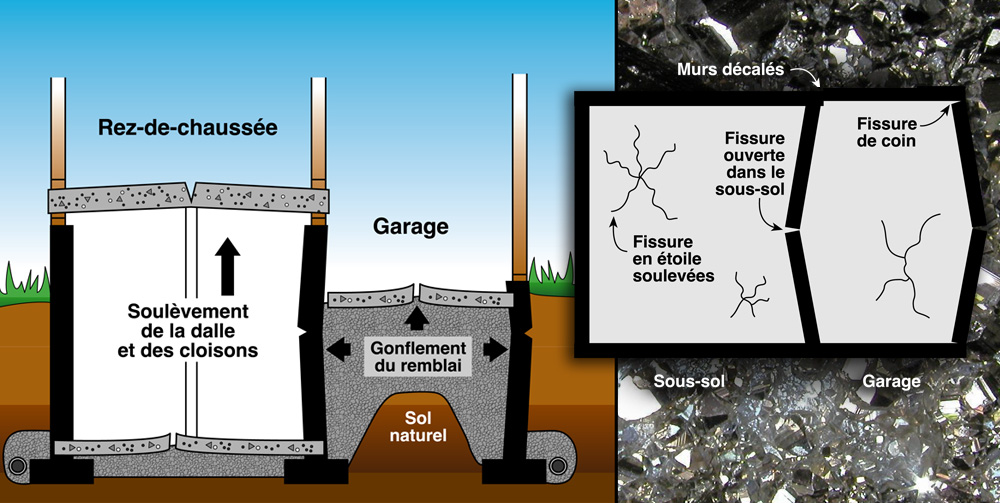

Pyrite is a sulphite mineral. Traces are found in sedimentary rock used to make crushed stone for backfill. In the presence of humidity and oxygen, pyrite oxidizes and produces sulphuric acid. This acid reacts with calcium carbonates found in crushed stone and concrete based products. This chemical reaction called sulphation forms gypsum whose crystallization will cause the stone to swell.

The swollen backfill may heave the slab and interior partitions resting on it. This may also damage floors, walls and even the roofs from upper floors and interior partitions. The greater the thickness of the backfill, and the greater the swelling is. This is why more swelling occurs in residential garages where the layer of the backfill is thicker (often up to one meter) than under basement slabs (typically 10 to 20 cm).

When sulphuric acid comes into contact with the bottom of the slab, the concrete swells from sulphation and starts disintegrating. The presence of a polyethylene vapour barrier placed under concrete slabs will contain sulfuric acid and virtually eliminate sulphation. Unfortunately, placing polyethylene under the slabs was not common practice before the year 2000. In the absence of a vapour barrier, sulphation disintegrates mostly the under surface of the slab and damage usually appear 10 or 20 years after construction. The swelling concrete expands the slab vertically and horizontally. As horizontal expansion is restrained by the foundation walls, heaving usually occurs towards the centre of the structure, sometimes creating large bulges which leave an empty space under the slab and producing raised star or cross-shaped cracks.

Reported Cases and Geographical Situation

Although this situation can affect all regions of Quebec, it is scientifically proven that some sectors are more naturally and seriously affected. This is particularly the case for the South Shore of Montreal, the eastern and western ends of the island of Montreal, Laval, the North Shore and the Lower Laurentians. Though, living in other geographic areas is not a reason to be certainly spared, as many isolated cases have been reported across the province.

The perfect example that no one can be free of concerns regarding this problem is illustrated by the misadventures of several residents of St.Lambert. These were sad and disappointment to note that despite the fact that their city is entirely built on the rock and thus considered by many experts as a zone free of pyrite, it was really found under their foundations. The problem was completely not related to the nature of the soil, but caused by the contaminated fill from quarries outside their city that had been used as fill for building up their home.

There are several solutions possible:

For existing structures, the best solution to swelling problems consists of replacing crushed stone with DB certified stone, and placing a geotextile membrane and a vapour barrier between the backfill and the concrete slab.

In 1999, the Comité technique québécois d'étude des problèmes de gonflement associés à la pyrite perfected a method of analysis, called CTQ-M-100, to eliminate the risks of swelling associated with this material. This certification permitted gravel producers to guarantee their clients that they were providing gravel that could be used without risk under concrete slabs for both construction and renovation. This gravel must have been analysed by one of the independent laboratories recognized by the technical committee and then designated "concassé certifié DB" (meaning DB certified gravel with the DB standing for "Dalle de Béton").

The laboratories use the IPPG unit of measure for both the CTQ-M-100 (new gravel) and the CTQ-M-200 (soil tests from under an existing structure).

For new material, if the IPPG index is less than 10, the material is immediately certified "DB", which means it is without any potential for swelling under a concrete slab. If the index is higher, the laboratory will continue with other tests before accepting or refusing a DB certificate to the gravel pit.

When the material being analysed came from under a concrete slab, the IPPG index has much less importance. In reality, a used material that has a high IPPG index could never swell, or could have already completely oxidized at the moment of the analysis without having caused any damage to the slab. What is important in this case is the judgment of the professional who is applying the CT-M-200 standard.

Steps to follow to solve the problem

For garage slabs, one must:

- Break and remove the concrete slab

- Excavate existing pyritic backfill (no deeper than the level of the footing)

- Seal all along the cracks by epoxy or polyurethane injection

- Consolidate the foundation walls with steel plate

- Place a geotextile membrane on undisturbed soil

- Backfill with DB certified material

- Put down a polyethylene vapour barrier

- Pour a new reinforced concrete slab

For basement slabs, one must:

- Remove interior partitions and false wood floors

- Break up and remove the concrete slab

- Excavate existing pyritic backfill

- Repair the foundation cracks from outside by epoxy or polyurethane injection

- Backfill with DB certified crushed stone

- Place a geotextile on undisturbed soil

- Put down a polyethylene vapour barrier

- Pour a new reinforced concrete slab

Contact us for a professional diagnosis, we are certified Reno-pyrite, we can guarantee that we will definitely get rid of pyrite.

Contact us

Contact Us

-

Address: 22, des Entreprises

Sainte-Anne-des-Plaines, QC J5N 1L2 -

Phone: 450 478-1014

Toll free: 514 877-5545

Fax: 450 478-7593 - Email: info@lesgoudronsduquebec.com

- We cover 100 km around Montréal (Laval, North Shore, Laurentians, South Shore)

- R.B.Q. : 1848-5052-38